Rolex watches are synonymous with luxury, precision, and timeless elegance. Renowned for their exceptional craftsmanship, engineering, and attention to detail, Rolex timepieces have become iconic symbols of success and prestige.

With a history dating back to 1905, Rolex has consistently pushed the boundaries of watchmaking and marketing, introducing innovative features and technologies through the years.

From the classic Datejust and Submariner to the sophisticated Day-Date and Cosmograph Daytona, Rolex offers a diverse range of models to suit various lifestyles and tastes. Each Rolex watch is meticulously crafted using high-quality materials, powered by precise movements, and designed to withstand the rigors of everyday wear.

A Rolex watch is not just a timekeeping device but a statement of style and accomplishment recognized the world over. In this article, we’ll dive deep into a specific part of Rolex watches: the watch bezel.

About Watch Bezels

Watch bezels serve both practical and aesthetic functions in wristwatches. A bezel is a ring-like component that surrounds the watch dial or face and is typically located between the crystal or glass covering and the watch’s case. While its primary purpose is to secure the crystal in place, bezels can also offer additional features and benefits depending on their design.

Protection & Durability

The bezel acts as a protective barrier for the watch face. It helps prevent scratches, impacts, and other forms of damage to the dial, as well as the crystal or glass covering. By creating a raised edge around the watch face, the bezel adds an extra layer of protection against accidental knocks or bumps.

Timekeeping & Measurement

Some watch bezels are specifically designed for timekeeping or measuring purposes. For example, diver’s watches often feature a unidirectional rotating bezel with minute markings to measure elapsed time underwater.

The wearer can align the bezel’s marker with the minute hand to track the duration of a dive or any other time-based activity. Similarly, some bezels are designed with tachymeter scales to calculate speed or chronograph functions for measuring elapsed time.

Aesthetic Enhancement

Bezels play a crucial role in the overall design and appearance of a wristwatch. They come in various materials, finishes, and styles to complement the watch’s aesthetics and create visual appeal. Whether it’s a simple, understated bezel or an elaborate, gemstone-encrusted one, the choice of bezel design can significantly influence the watch’s overall look and feel.

Functional Indicators

In certain watches, bezels can serve as functional indicators or markers. For example, a pilot’s watch might have a bi-directional rotating bezel with a slide rule function to assist with calculations related to aviation, such as fuel consumption or airspeed. These bezels often feature specialized markings or scales that aid in performing specific calculations or conversions.

Versatility & Customization

Some watches feature interchangeable bezels, allowing wearers to change the appearance or functionality of their timepieces easily. These modular bezel systems enable users to swap out bezels of different colors, materials, or functions, providing versatility and personalization options to match various occasions or preferences.

It’s worth noting that not all watches incorporate a functional bezel. Some timepieces, particularly minimalist or dress watches, may have fixed bezels that focus primarily on aesthetics while keeping the watch face unobstructed.

In such cases, the absence of a functional bezel doesn’t diminish the watch’s overall value or functionality; instead, it reflects a design choice aimed at achieving a specific style or purpose.

Current Types of Rolex Bezels

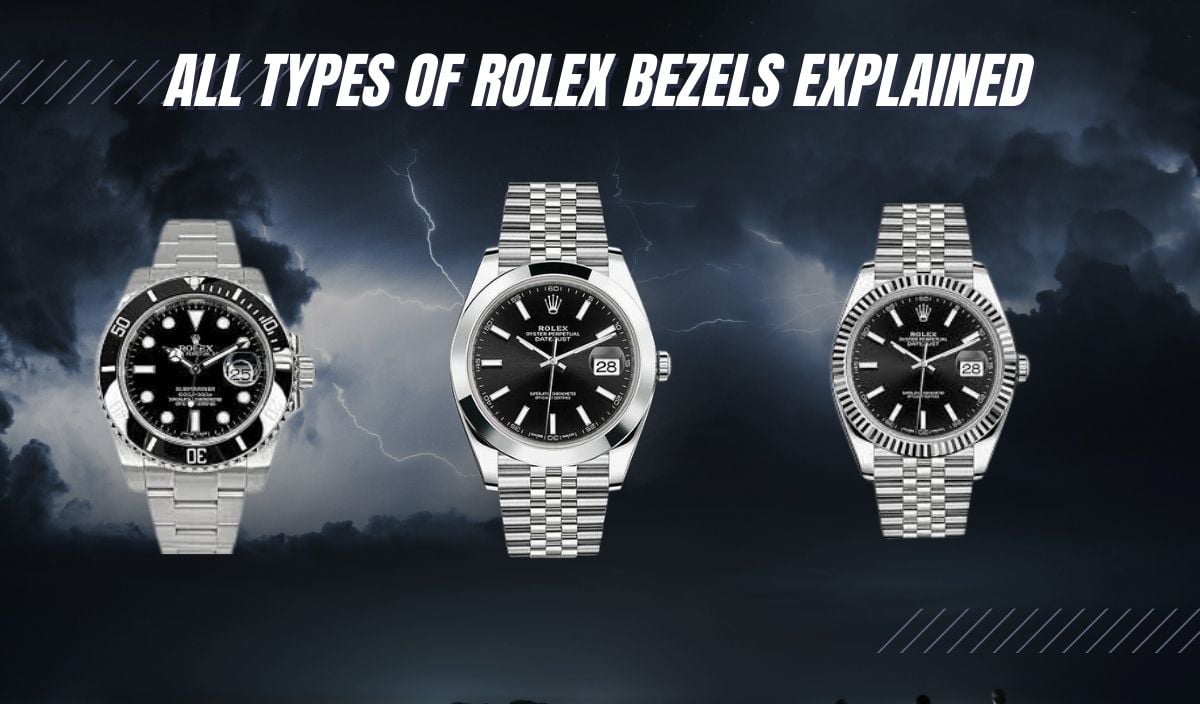

Rolex watches are known for their attention to detail and precision craftsmanship, and the bezels they use are no exception. Rolex offers a range of different bezel types across their various watch models, each serving a specific purpose and catering to different needs. Here are some of the notable bezel types used by Rolex:

Smooth/Domed Bezel

The Rolex smooth bezel is a hallmark of elegance and sophistication, with just the right touch of sportiness. Found on models such as the Oyster Perpetual, Datejust, and Day-Date, and professional models like the Air King and Explorer, this bezel type showcases a sleek and polished surface devoid of any additional markings or textures.

Its simplicity allows the focus to remain on the dial and overall design of the watch. The smooth bezel complements various styles, from formal occasions to everyday wear, making it a versatile choice for everyday wear. Crafted with meticulous attention to detail, Rolex ensures that the smooth bezel seamlessly integrates with the watch case, creating a cohesive and harmonious aesthetic.

This understated bezel design adds a touch of refined class to the timepiece, making it a timeless and elegant accessory for discerning individuals who appreciate the art of understated luxury.

Fluted Bezel

The Rolex fluted bezel is an iconic and instantly recognizable feature of many Rolex watches, most notably the Datejust and Day-Date models. This distinctive bezel design showcases vertical ridges or grooves that encircle the outer edge, resembling the edge of a coin.

The fluted bezel adds a touch of sophistication and character to the timepiece, elevating its aesthetic appeal. Carved with high precision, the fluted bezel also serves a practical purpose, allowing for easy gripping and manipulation when installing the bezel above the sapphire crystal. This bezel design enhances the watch’s visual allure and serves as a hallmark of Rolex’s attention to detail and craftsmanship.

The Rolex fluted bezel has become the brand’s symbol and trademark feature, making it a coveted feature for those seeking a luxurious and recognizable timepiece. Recently, Rolex released the Perpetual 1908 dress watch collection, featuring finer coin edge ridges set into the bezel.

Diamond-Set Bezel

Rolex gem-set bezels represent the pinnacle of luxury and glamor. These bezels are adorned with carefully selected and expertly set precious gemstones, including diamonds, sapphires, or other exquisite gems.

Rolex offers gem-set bezels on select models such as the Datejust and Day-Date, and even on sports models such as the Submariner, GMT Master II, and Daytona, enhancing their already distinguished designs.

The gemstones are expertly placed into the bezel, ensuring precise alignment and a captivating display of brilliance and light play. Rolex’s strict quality standards guarantee that only the finest diamonds and gemstones are used and chosen for their exceptional clarity, color, and cut. The gem-set bezels elevate the watch’s allure, catching the light from every angle and turning heads with a dazzling presence.

Among the Crown’s technical achievements and prowess, their in-house gem-setting represents the epitome of opulence, making these timepieces a coveted choice for those who seek the highest levels of watchmaking from the brand.

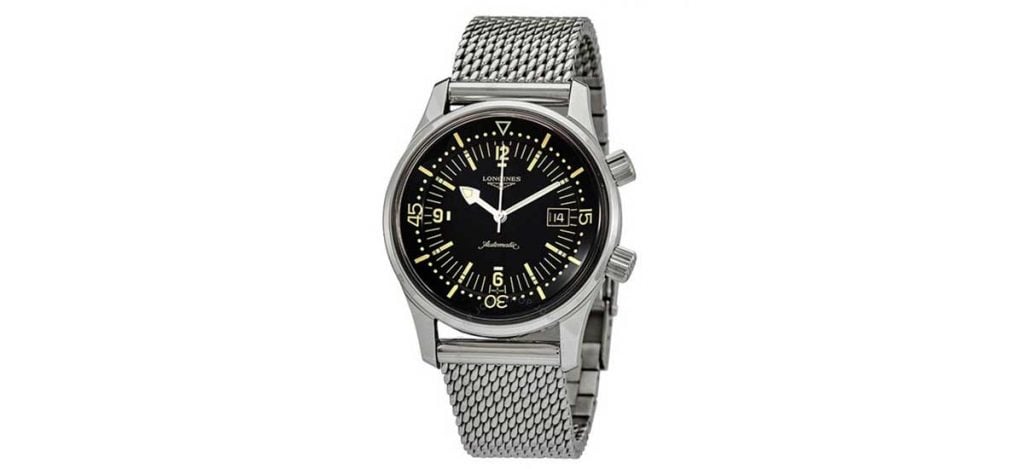

Rotatable Bezel

Among the Rolex catalog, both unidirectional and bidirectional rotating bezels are available on specific watch models for added function. Of the unidirectional variant, both the Submariner and Sea Dweller collections feature rotating bezels designed for diving. Either model’s bezels feature minute markings, allowing divers to accurately measure their elapsed dive time by aligning the bezel’s marker with the minute hand.

Made from robust materials like ceramic or aluminum (in older generations), Rolex diving bezels are known for their durability and resistance to wear. In the Yacht Master, a bidirectional rotating bezel with a raised 60-minute scale is utilized.

This bezel is designed for regatta timing, allowing wearers to measure precise intervals. It adds a sporty and nautical touch to the watch’s aesthetics, a bit more modern leaning than the traditional dive bezels mentioned earlier.

24-Hour GMT Bezel

The rotating GMT bezel is a distinct and practical feature found on the GMT-Master II collection, designed specifically for tracking multiple time zones. The bezel, made of robust materials like ceramic or aluminum (in previous generations), incorporates a 24-hour scale that allows wearers to easily reference a second timezone.

The GMT bezel is bidirectional, enabling smooth and convenient adjustment. It can be rotated in either direction to align the 24-hour scale with the GMT hand on the watch dial.

By setting the GMT hand to the desired second time zone and aligning it with the bezel, wearers can effortlessly keep track of two different time zones simultaneously. This functionality proves invaluable for travelers, pilots, and individuals who frequently deal with international time differences. It allows for quick and efficient time zone adjustments without affecting the accuracy of the watch’s primary timekeeping function by utilizing the crown for adjustment.

Tachymeter Bezel

The tachymeter bezel on the Rolex Daytona is a functional and iconic feature that enhances the watch’s chronograph capabilities. The bezel incorporates a tachymeter scale, which allows wearers to measure average speed over a known distance using the chronograph function.

The tachymeter scale is engraved or printed (as on older models) on the outer edge of the bezel and typically ranges from 60 to 400 units per hour. It enables users to calculate speed based on the time taken to cover a specific distance. When the chronograph is activated, the wearer starts timing and stops it after traveling the desired distance.

The chronograph second hand points to the tachymeter scale, indicating the average speed. The tachymeter bezel on the Daytona is a functional tool and adds a sporty and dynamic touch to the watch’s overall design, reflecting the model’s racing heritage and its association with speed and precision.

Ring Command Bezel

The Rolex Yacht-Master II is equipped with a unique and innovative feature known as the “Ring Command” bezel. This specialized bezel is an integral part of the watch’s mechanical movement and allows for manipulating complex functions with haptic ease.

The Ring Command bezel operates in conjunction with the watch’s programmable countdown timer, which is designed specifically for yacht racing. By rotating the bezel counterclockwise, it engages and unlocks the timer function. From there, the bezel can be turned further to set the desired countdown time.

Once the countdown begins, the bezel remains stationary, ensuring accurate timekeeping.

The functionality of the Ring Command bezel lies in its intricate internal mechanism, which interacts with the watch’s movement to control the countdown timer. This innovative design enables precise and intuitive operation, allowing sailors to focus on their race preparations without any complexity.

Other Notable Types of Rolex Bezels

Outside of the current catalog’s range of bezel configurations, Rolex has historically utilized other types of bezels which are no longer in production, whether due to style and taste preferences changing through the years or streamlining of manufacturing across their product offerings today. Let’s explore this further.

Engine Turned Bezel

No longer in production, the Engine Turned Bezel, commonly featured in historic collections such as the Air King, Datejust, Oyster Perpetual, and Date models, was a practical alternative for those seeking a design less formal than a fully fluted bezel, yet not as stark as a smooth domed bezel.

Bark Bezel

Also no longer being produced, the bark bezel was utilized mainly on Day-Date and a small number of Datejust watches and featured even finer ridging along the surface of the bezel (quite like the texture of bark) than a traditional fluted bezel in fine materials like yellow and white gold.

Pyramid Bezel

As the name suggests, the Pyramid bezel featured pyramid-shaped decorative carvings on the bezel. Found on dressier pieces and often paired with gem set detailing, the Pyramid bezel was utilized on Day Date, Oysterquartz Day Date, as well as Lady Datejust timepieces.

Florentine Bezel

The Florentine bezel is a very fine, almost filed-like texture which was rarely used on particular Datejust and Oyster Perpetual models. Adding a finer texture to what otherwise would be a traditional smooth bezel, it’s a particularly refined look not often seen in the brand’s catalog.

Moreau Bezel

Not widely produced or replicated, the Moreau bezel is a rare bezel type from the Crown, which featured a hashmark mix of engraving and textured finishing on select gold Date and Datejust models.

Greek Key Bezel

Echoing emblematic Greek decoration and patterning, the Greek Key style bezel from Rolex was only available on special order from the brand, particularly on the reference 1506 Date. Its deep etchings replicate Greek art patterns along the circumference of the bezel, much as the name suggests.

Moiré Bezel

Similar to the Moreau bezel mentioned prior, the Moiré bezel features small flutings directed inwards towards the dial, as well as flutings crossing against them horizontally around the full circumference of the bezel. The result is a unique texture with an almost antiquated handcraft feel.

Zephyr Bezel

The Zephyr Bezel was featured on the Oyster Perpetual “Zephyr”, produced between the 1950s and 1970s. It features fine fluting and small cut notches at each minute mark on the inner side of the bezel, which the wearer could use as “hashes” for minute markings outside of the dial in practical use.

Morellis Bezel

Rarely seen, the Morellis bezel is a gold leaf-like texture that is crisp and refined when found on rare Day Date models during the 1960s. The center links of the accompanying president-style bracelets also feature the gold leaf “Morellis” texture, producing an overall impressive if not stark look when compared to fully polished or fluted alternatives.

Conclusion

Over the decades since the brand’s inception, Rolex has continually offered and improved upon its bezel designs across its full range of timepiece offerings. It’s important to note that not all bezel types are available on every Rolex model. Specifically, the choice of bezel type, construction, and materials, depends on the watch’s intended purpose, design, and target audience.

As a watchmaking and engineering powerhouse of the industry, Rolex has, through the years, selected and designed bezels that align with the functionality and aesthetics of each watch model, ensuring a harmonious and purposeful timepiece.