How Mechanical Watches Work

Ask any watch collector or self-confessed timepiece enthusiast. We guarantee they’ll be more than happy to talk about mechanical watches, probably for hours, and explain to you just how innovative and breathtaking these timeless pieces are.

Whether manually wound or powered by the movement of your wrist, mechanical watches have remained a symbol of craftsmanship and precision since their birth. Unlike quartz watches, which rely on a battery, mechanical watches utilize several intricate components to keep time.

So, just in case you’re new to the world of horology – that’s the fancy word for the art of watchmaking – and you don’t have an avid watch connoisseur in your life, let us guide you through all there is to know about mechanical watches including how they work, their history and how best to maintain then.

The Basics of a Mechanical Watch

Ok, so before we get into the nitty-gritty details of how a mechanical watch works, let’s first cover the basics. At the heart of any watch, there is something called a movement. This is the technology used to make the hands tick seamlessly around the dial so you can read the correct time. There are two key types of watch movements: quartz and mechanical.

Quartz watches are those powered by a small battery that needs replacing every couple of years. The battery relies on electricity and the properties of a quartz crystal, allowing quartz watches to be incredibly accurate and low maintenance. Mechanical watches, on the other hand, work completely differently. They don’t use batteries but instead rely on a series of tiny moving parts to keep time.

There are two types of mechanical movements: manual winding and automatic. Manual winding watches need to be wound by hand. You turn the crown (the little knob on the side of the watch), and this winds a component called the mainspring. As the mainspring unwinds, it releases stored energy that powers the movement, keeping the watch ticking.

Automatic watches work similarly, except they have a small, semi-circular weight inside called a rotor, which winds the mainspring automatically as you wear the watch. The natural motion of your wrist makes the rotor spin, keeping the watch wound without you needing to do anything. If you wear it daily, it’ll keep ticking forever.

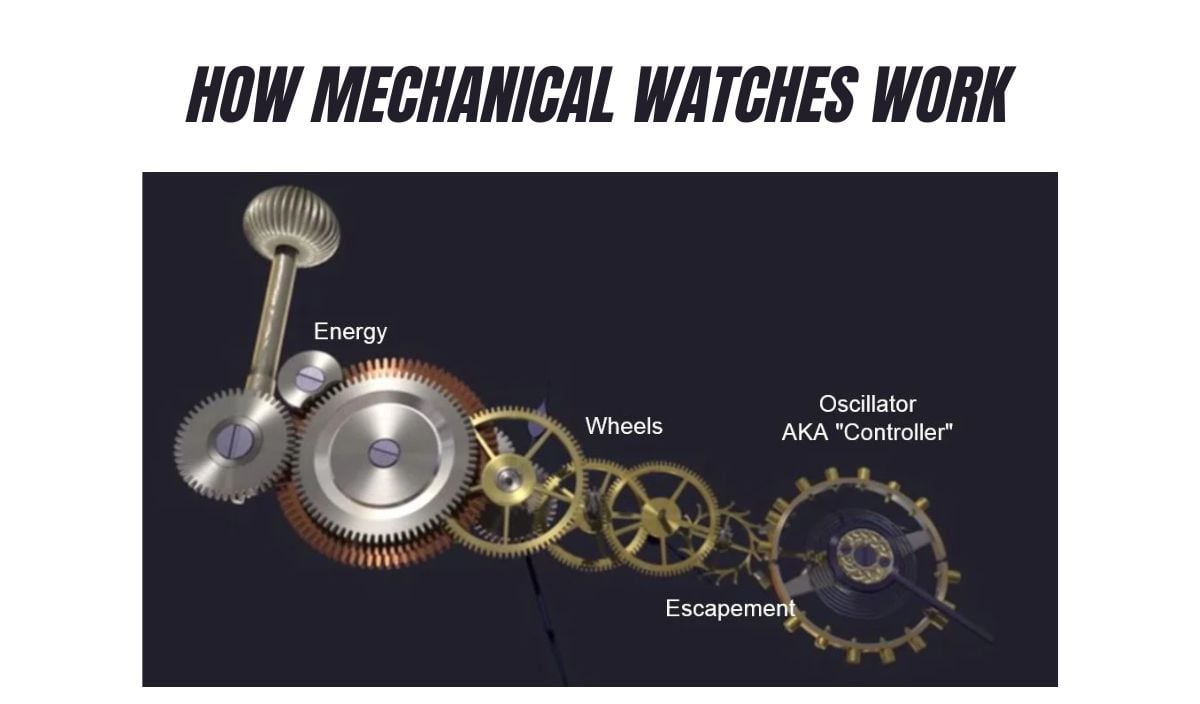

It’s these tiny, intricate parts that make a mechanical movement truly special. As you’ve probably realized, the mainspring is one of the most important components, as it’s this that needs winding to power the watch.

It works by winding up and storing the energy needed to fuel the other components. This energy is then transmitted through the gear train, an escapement and a balance wheel, all of which work together to ensure the watch runs steadily and accurately.

History of Mechanical Watches

Mechanical watches date back centuries, with some of the first recorded mechanical clocks emerging from Europe during the late 13th century. But these were large tower clocks and not the wristwatches we know today.

It wasn’t until the 16th century that the components of mechanical movements were made small enough to fit into portable, wearable watches. Some of the earliest mechanical watches were powered by a mechanism called the Verge escapement, an innovation that helped watches become more compact and wearable.

The first true mechanical watch was developed by Peter Henlein, a German locksmith, around 1510. His invention, often credited as the first portable timepiece, was a spring-powered pocket watch. However, it was far from accurate— as you’d expect for the world’s first-ever attempt. Instead, these early watches were mostly decorative, meant to showcase wealth rather than tell precise time.

Accuracy in mechanical watches became a major focus in the 18th century. John Harrison, an English carpenter and clockmaker, invented the marine chronometer, which revolutionized timekeeping as we know it.

His device allowed sailors to determine longitude at sea, a breakthrough in navigation. This leap in precision marked the beginning of mechanical watches being valued not just for their beauty but for their accuracy.

As time went on, mechanical watch movements continued to evolve. The COSC certification (Contrôle Officiel Suisse des Chronomètres) was introduced to set a high standard for accuracy in Swiss watches.

To receive COSC certification, a mechanical watch must meet strict criteria, such as keeping time within -4 to +6 seconds per day, a mark of precision that separates ordinary watches from exceptional ones. Having a COSC-certified watch means you have the confidence your fancy wristwatch has passed several rigorous tests to prove its timekeeping abilities.

Today, mechanical watchmaking has reached entirely new heights with innovations like the Zenith El Primero. Launched in 1969, this has become famed for being the world’s first automatic chronograph movement. It not only automated the winding process but also boasted a frequency of 36,000 vibrations per hour, making it one of the most precise mechanical movements of its time.

The Grand Seiko Spring Drive is another notable innovation. This engineering marvel has somehow combined the mainspring of a mechanical movement with the electronic regulator of a quartz one. This hybrid technology allows for a completely smooth seconds hand and near-perfect precision.

Operating a Mechanical Movement

Until you’ve seen one up close, it’s difficult to explain just how incredible and innovative mechanical watch movements are. But we’ll try our best!

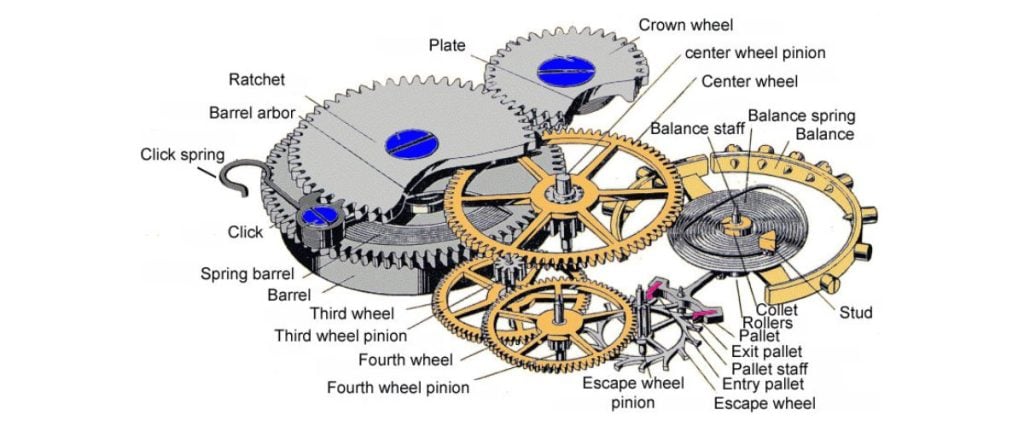

These miniature marvels of engineering are powered by hundreds of tiny parts that all work together to keep the time showing on the dial accurate. Let’s break down the key parts of a mechanical watch and see how they work together to create a functioning timepiece.

The Mainspring

Many will agree that the mainspring is the heart of a mechanical watch. It’s a long, thin strip of metal wound tightly into a coil, and its job is to store energy. In a manual winding watch, you wind the watch by turning the crown, which tightens the mainspring. In an automatic watch, the winding happens naturally as you move your wrist, thanks to a rotor inside the watch that spins and winds the spring.

As the mainspring unwinds, it releases the stored energy. The more tightly it’s wound, the more energy it stores, and the longer the watch can run. A fully wound mainspring can typically power a watch for about 40 hours, though some high-end watches offer much longer power reserves. The energy released by the mainspring powers the entire movement.

However, it doesn’t release all the energy at once, but it does so slowly, over time. The process of controlling this energy flow is where the rest of the watch’s components come into play.

The Gear Train

Once the mainspring begins to release energy, it sends it through the gear train, a series of small gears that transmit the energy throughout the movement. These gears reduce the speed of the energy unwinding from the mainspring so that the hands on the watch move at the correct speed.

At the start of the gear train, energy is moving very fast, but by the time it reaches the hands of the watch, it has been slowed down enough to turn the second, minute, and hour hands at their proper speeds. The gear train ensures that one complete rotation of the minute hand happens every 60 minutes and one rotation of the hour hand happens every 12 hours.

The Escapement

The escapement is another super important component of a mechanical watch because it controls the release of energy from the mainspring. Without it, the mainspring would unwind too quickly, and the watch would lose all its energy in seconds.

The escapement acts almost like a gatekeeper, releasing tiny amounts of energy in controlled intervals. This gives the watch its steady “tick-tock” rhythm. It also works in conjunction with the balance wheel (which we’ll get to next) to regulate the speed at which the gears turn and the hands move.

In most mechanical watches, the escapement consists of two main parts: the escape wheel and the pallet fork. The escape wheel is connected to the gear train, and the pallet fork alternately locks and unlocks it, allowing the wheel to move forward one step at a time.

Each time the escape wheel moves, a tiny burst of energy is sent to the rest of the movement, allowing the gears to turn in perfect time.

The Balance Wheel

Working closely with the escapement is the balance wheel, which is like the watch’s pendulum. The balance wheel oscillates back and forth at a constant rate, and this regular motion helps the escapement release energy in evenly spaced intervals. Attached to the balance wheel is a tiny, coiled spring called the hairspring or balance spring.

As the balance wheel swings in one direction, the hairspring tightens. Then, it loosens, pushing the balance wheel back in the opposite direction. This process repeats over and over, giving the watch its rhythm.

The oscillations of the balance wheel, typically 18,000 to 36,000 beats per hour, determine how quickly the escapement can unlock and release energy. The faster the balance wheel oscillates, the more precise the watch will be.

The Dial Train and Hands

The dial train is a series of gears that takes the controlled energy from the escapement and balance wheel and uses it to drive the hands of the watch. It reduces the speed of the gear train so that the second, minute, and hour hands move at their respective speeds.

For example, the second hand completes one full rotation every 60 seconds, the minute hand completes one rotation every 60 minutes, and the hour hand completes one rotation every 12 hours. The dial train ensures that these rotations happen precisely and smoothly.

The Rotor (for Automatic Watches)

For automatic watches, there’s an additional component called the rotor. This is a semi-circular weight that spins as you move your wrist, winding the mainspring in the process. The rotor pivots around a central axis, and when it spins, it transfers energy to the mainspring, keeping the watch wound without the need for manual winding.

The beauty of the rotor is that it uses the natural movement of your body to keep the watch running. If you wear your watch regularly, it will stay wound without you ever having to manually wind it.

The Crown

The crown is the small knob on the side of the watch that you use to wind it manually. In most watches, you can pull the crown out to adjust the time or push it in to wind the mainspring.

Automatic watches can also be wound manually if the rotor hasn’t wound enough through natural movement. The crown is your main point of interaction with the mechanical movement, and it plays a crucial role in keeping the watch running smoothly.

Mechanical Watch Maintenance Tips

As is the case with any watch, mechanical watches require some love and care to keep them ticking for years. One of the most important and possibly obvious tips we can give you is to keep your mechanical watch wound.

For many watches, make sure to wind the crown gently once per day, preferably at the same time each day. If you have an automatic watch but you don’t wear it daily, you might want to consider getting a watch winder to keep it running.

Another key tip is to avoid exposure to magnets, as they can affect the watch’s accuracy. Keep your mechanical watch away from electronic devices like smartphones, speakers, and laptops, which emit magnetic fields, as these can mess with those intricate components inside and ultimately ruin the precision and functionality of your timepiece.

Similarly, we also suggest keeping your watch clean. Wiping it with a soft, dry cloth every now and then will help to prevent any dust, dirt, or sweat from getting into the movement. This will also help keep your watch looking brand new.

Depending on the water resistant rating of your mechanical watch, try to avoid submerging it in water. And even if your watch is water resistant, check the seals periodically. This can also be done when you service your watch, which should be actioned by a professional every 3 to 5 years.

Over time, the oils inside the movement can dry out, and the tiny gears can wear down, so the regular maintenance provided by a watch service ensures your watch keeps performing at its best.

Conclusion

Hopefully, you can now see why so many of us watch nerds and why we love the beauty and technology of mechanical watches. These little works of art require no battery, but just a selection of finely tuned gears, springs, and wheels to tell the time.

Whether manually wound or automatic, mechanical watches represent centuries of horological innovation. Sure, they’re not as accurate as quartz watches, but those battery-operated movements lack the artistry, engineering, and history that comes with a true mechanical timepiece.

About Exquisite Timepieces

Established in 1998, Exquisite Timepieces is your one-stop shop for all things luxury watches! We are an authorized dealer for 60+ luxury watch brands including Omega, Hublot, Seiko, & Longines! We are proud to showcase one of the world’s largest pre-owned watch collections, including renowned brands like Rolex and Patek Philippe. Check out our brand new watch arrivals here and popular pre-owned listings here.